Industrial - Honours

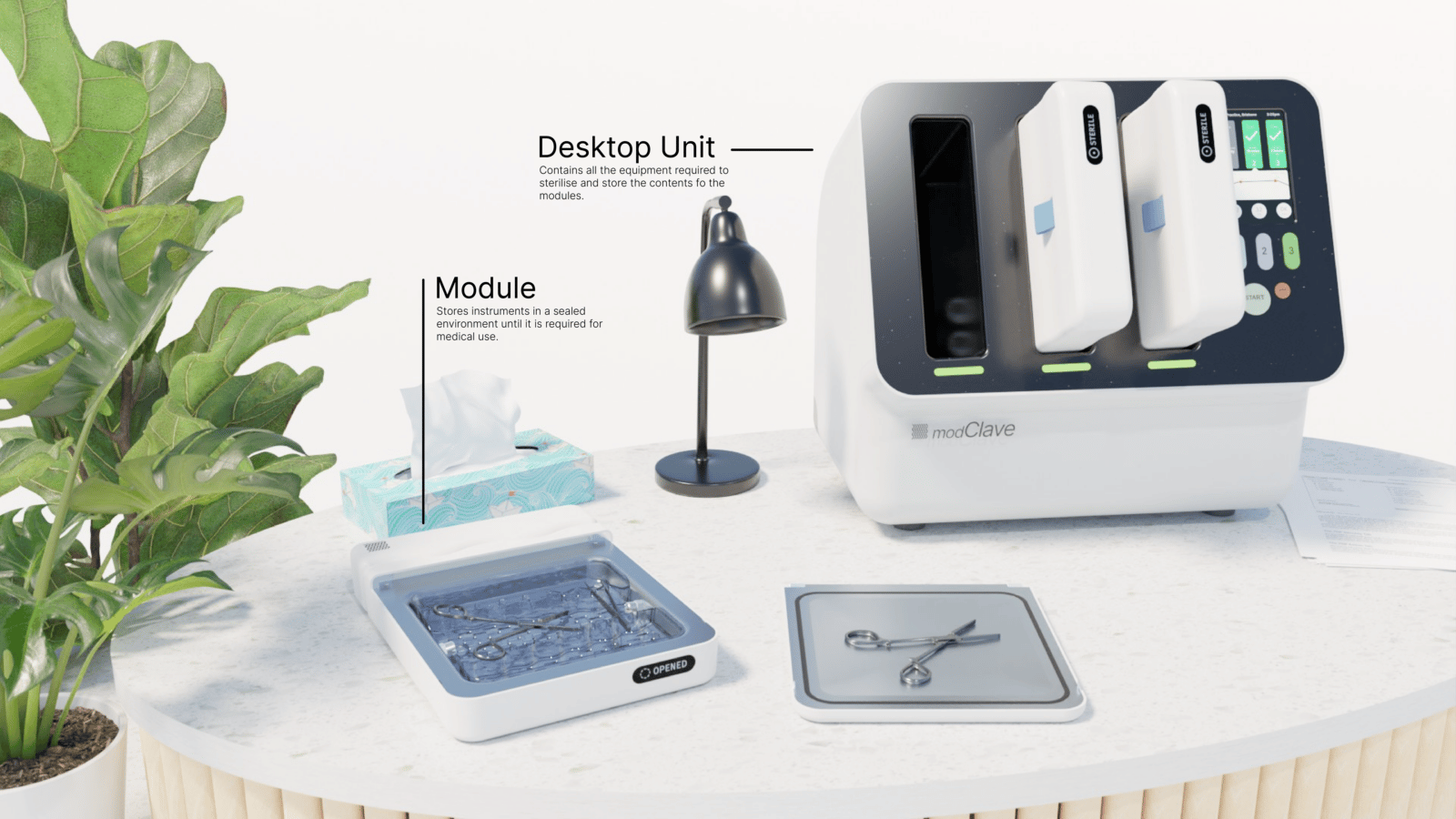

modClave: Store & Sterilise

Awarded

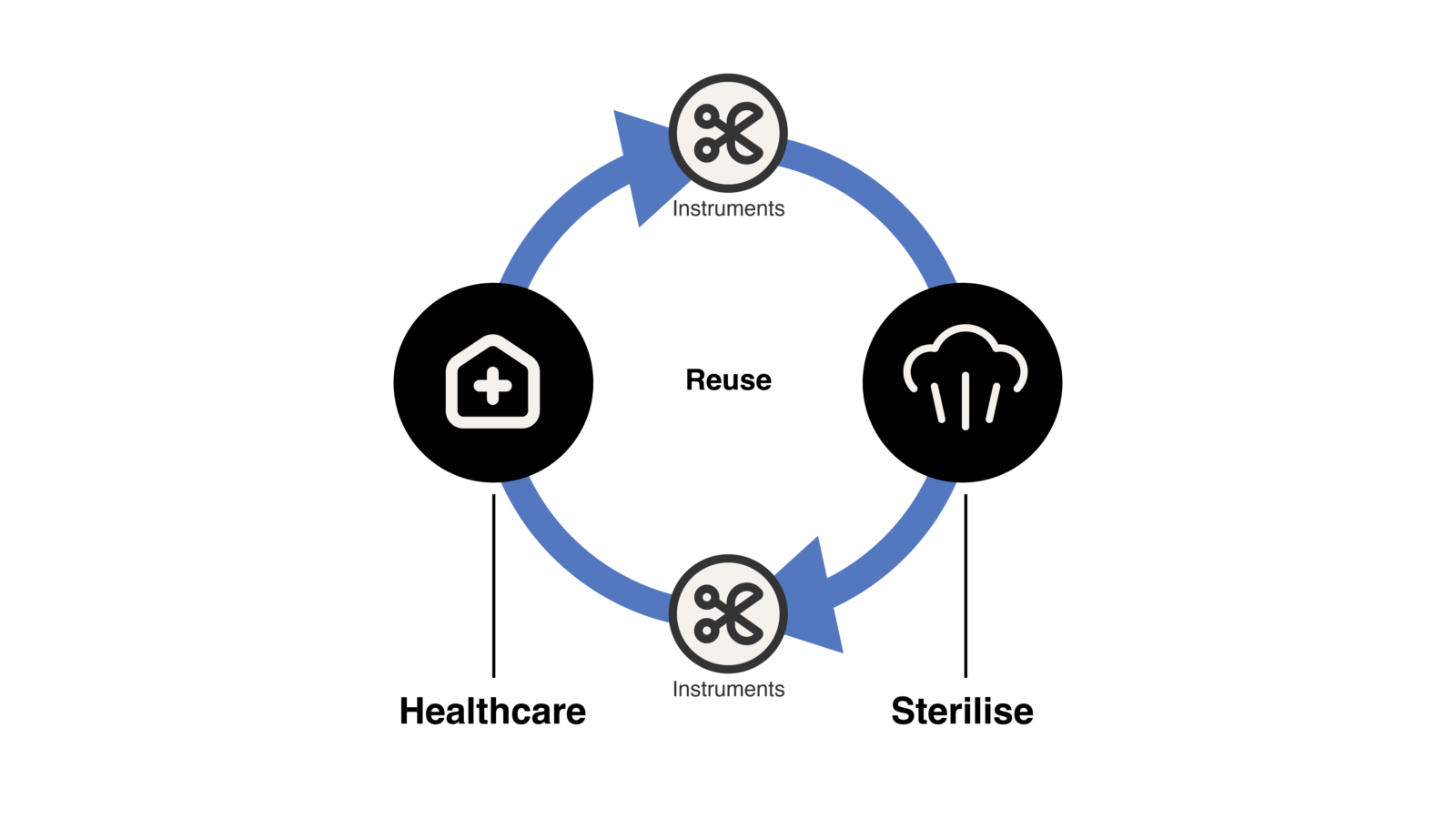

The modClave is a module-based steam sterilisation desktop appliance that enables small to medium-sized private medical practices to reprocess reusable metalware instruments such as scissors, tweezers and forceps. This product solves pain points discovered in the research phase where traditional autoclaves are often too expensive for clinics with the rise of western wages and the cost of commercial space. These pressures have led many clinics to increase their reliance on single-use instruments that are often hardly used before they have to be thrown away.